Metallic material

Innovation | Professionalism

Integrity | Efficiency

Metallic material

Innovation | Professionalism

Integrity | Efficiency

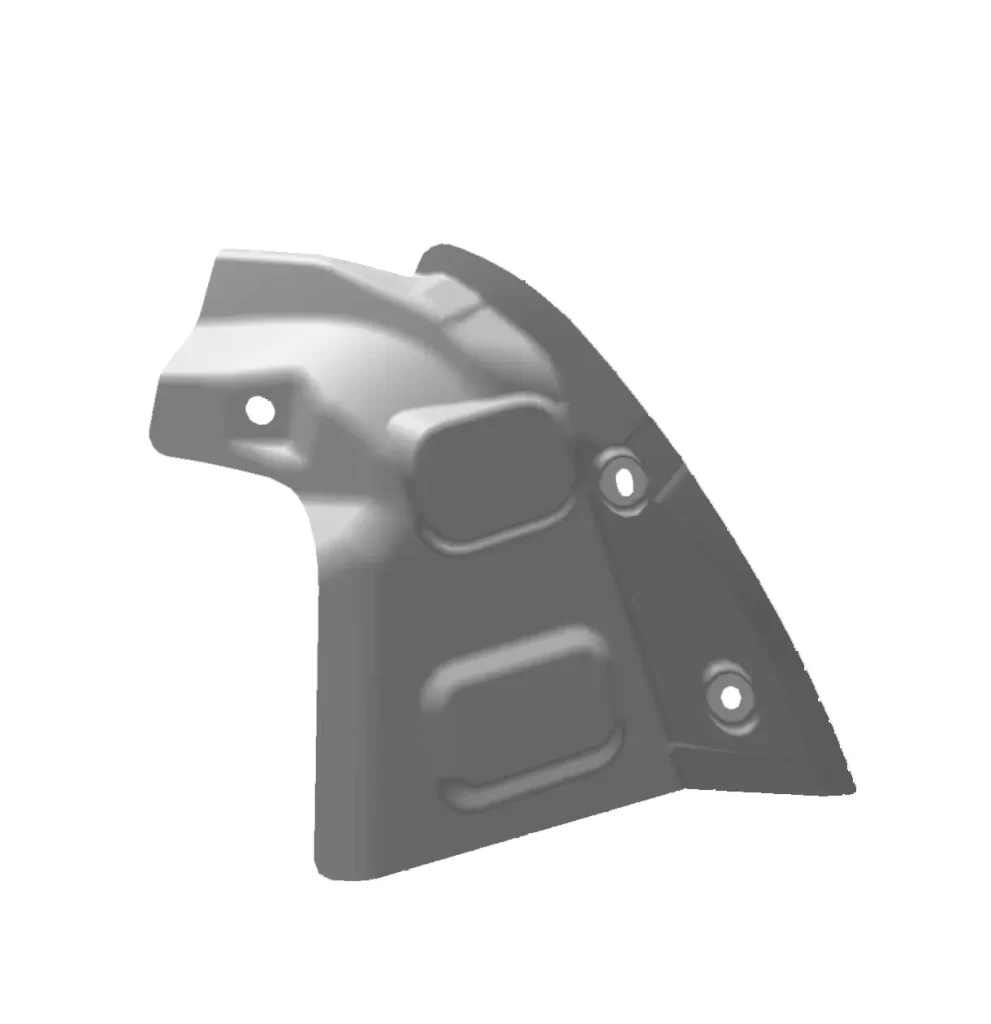

Upper A-pillar Reinforcement is a steel plate used to strengthen the upper structure of the A-pillar of a car. It is usually installed inside the A-pillar and close to the surface of the A-pillar to enhance the rigidity and safety performance of the car body.

The A-pillar is an important part of the body structure, responsible for supporting the connection between the roof and the frame, and protecting the driver and passengers in the event of a side collision. On the upper part of the A-pillar, due to the load of the roof and the influence of the height and weight of the vehicle body, it is easy to bend or deform. Therefore, it is necessary to install Upper A-pillar Reinforcement to enhance the rigidity and stability of the A-pillar to improve The overall strength and crash safety performance of the car body.

Usually, Upper A-pillar Reinforcement is made of high-strength steel sheet, which can be designed and customized according to different models and requirements. Where and how it is installed may vary by model and manufacturer, but in general, it is an important safety component that plays an important role in improving the safety performance of the car.

The process of producing hot-formed steel involves heating the billet to a temperature above its austenitization point, maintaining it at that temperature for a specific duration, and then subjecting it to a press and quench method to create a martensitic structure. This process results in parts with exceptional strength and toughness, which in turn enhances their resistance to collisions. Hot-formed steel is particularly useful in the manufacture of body structural parts, especially those designed for intrusion-proof security purposes.

The Upper Reinforcement Panel is a steel panel used to strengthen the car body structure, usually above the roof, to enhance the rigidity and torsional performance of the car body.

The upper beam in the car body structure is a structural member connecting the left and right B-pillars, responsible for supporting the connection between the roof and the bottom of the body, and bearing the weight of the body and external impact. However, when driving at high speed or in a collision, the upper part of the vehicle body will be affected by twisting force. It is necessary to install a side sill reinforcement plate to increase the rigidity and torsion resistance of the vehicle body to ensure the stability and driving safety of the vehicle.

The Upper Reinforcement Panel is usually made of high-strength steel plates. Its design and installation location may vary depending on the model and manufacturer, but it is usually close to the roof, connected to the upper part of the B-pillar from the left and right sides, and connected to the A , C-pillar and other structural parts are connected together to form an integral body structure.

Dual-phase steel is characterized by a microstructure consisting mainly of ferrite and martensite. The martensite structure is distributed throughout the ferrite matrix in the form of islands. This unique structure provides the steel with a low yield ratio, a high work hardening index, and a bake hardening value, making it an ideal material for automotive structural parts. Due to its exceptional properties, which allow for increased strength and durability in structural components.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC550/980DPD+Z | 550-730 | ≥980 | ≥10% | – | – | – |

Grade: HC550/980DPD+Z

C(max): 0.23

Mn(max): 3

Si(max): 1

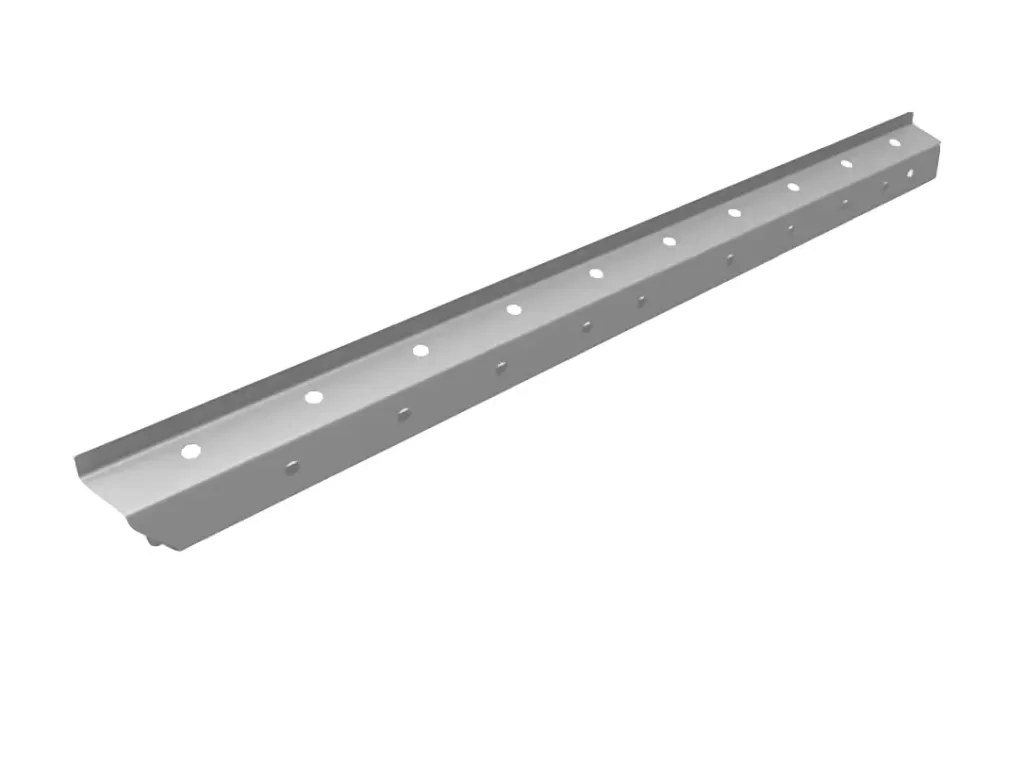

Rocker Panel Reinforcement is a type of steel plate or beam used to reinforce the rocker panel area of a vehicle. The rocker panel is the area between the front and rear wheel wells along the lower edge of the vehicle’s body, and it is susceptible to damage from debris or impact during normal driving.

The purpose of the Rocker Panel Reinforcement is to provide additional support and strength to this area of the vehicle’s body, which is critical for maintaining the vehicle’s structural integrity and safety in the event of a collision. The reinforcement is typically made of high-strength steel and is designed to fit snugly against the rocker panel, providing an additional layer of protection against damage.

Q&P steel is a type of steel that contains martensite as well as a significant amount of ferrite, and approximately 8% to 12% retained austenite. This steel is notable for utilizing the transformation-induced plasticity effect of retained austenite during deformation, which enables it to achieve higher levels of work hardening performance and elongation. Compared to high-strength steel of a similar strength level, Q&P steel offers superior plasticity and formability. This makes it an ideal choice for applications that require a balance between strength and ductility.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC820/1180QPD+Z | 820-1100 | ≥1180 | ≥8% | – | – | – |

Grade: HC820/1180QPD+Z

C(max): 0.25

Mn(max): 3

Si(max): 2.5

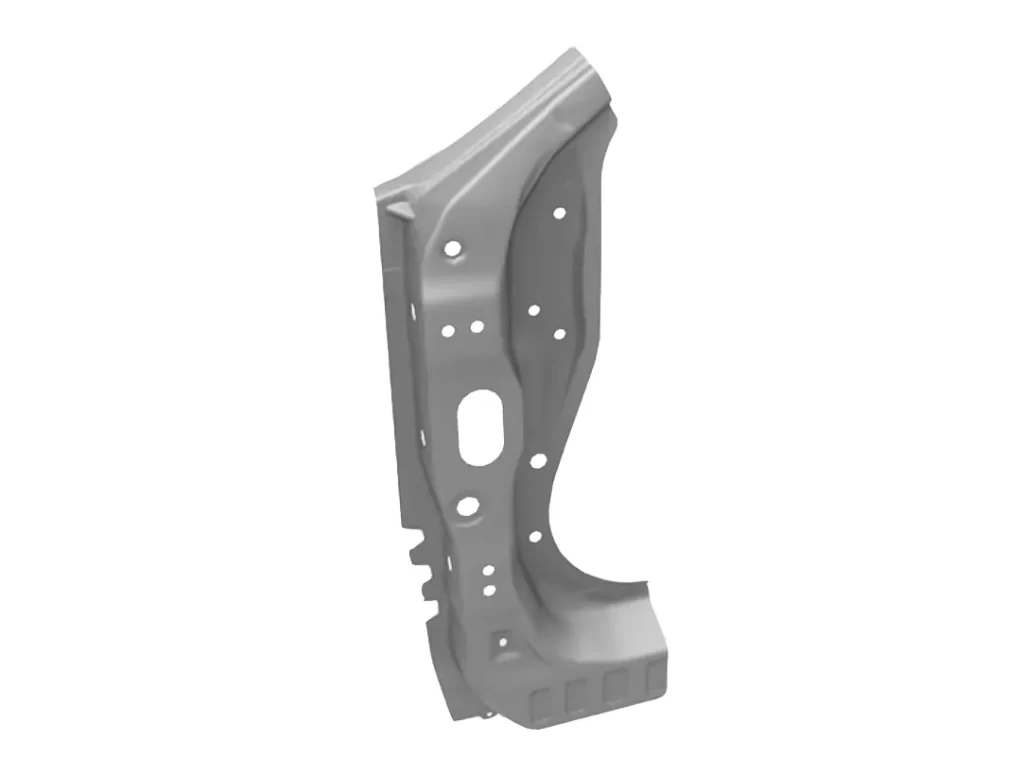

Lower A-pillar Reinforcement is a steel plate or beam that is installed in the lower section of the A-pillar of a vehicle’s body structure. The A-pillar is the vertical support that connects the front of the vehicle’s roof to its body, and it is a critical component of the vehicle’s safety structure.

In the event of a frontal collision, the A-pillar is subjected to significant forces that can cause it to deform or collapse, compromising the structural integrity of the vehicle and increasing the risk of injury to the occupants. The Lower A-pillar Reinforcement is designed to provide additional support and strength to this critical area of the vehicle’s body structure, helping to distribute the impact forces more effectively and reducing the risk of deformation or collapse.

Hot-formed steel is produced by heating a billet above its austenitization temperature, holding it for a specific duration, and then rapidly quenching it to create a martensitic structure. This process results in parts that are characterized by high strength and toughness, which greatly enhances their anti-collision performance. Hot-formed steel is typically utilized in the manufacture of body structural parts, particularly those intended for intrusion-proof security purposes.

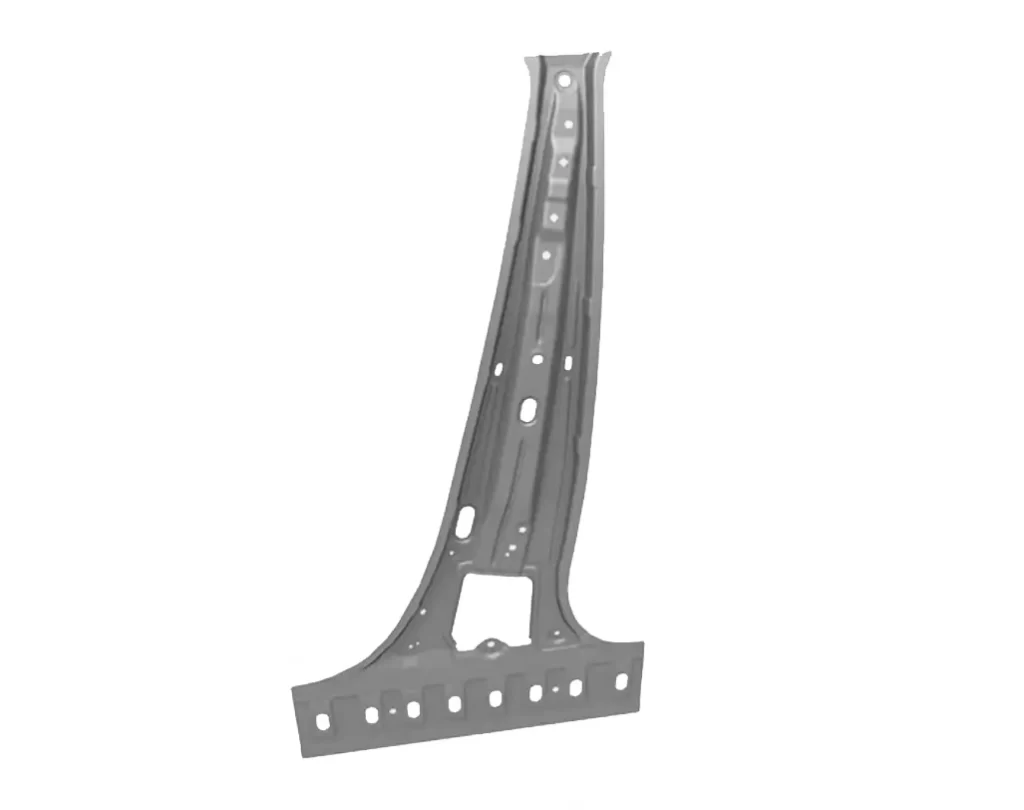

B-Pillar Reinforcement is a structural component of a vehicle’s body that is designed to increase the strength and rigidity of the B-pillar. The B-pillar is the vertical support located between the front and rear doors of a vehicle, and it plays a critical role in maintaining the structural integrity and safety of the vehicle.

B-Pillar Reinforcement is typically made of high-strength steel and is designed to fit snugly against the B-pillar. It is installed to provide additional support and strength to the B-pillar, which helps to distribute the forces of a collision more effectively and reduce the risk of deformation or collapse.

Hot-formed steel is produced by heating a billet above its austenitization temperature, holding it for a specific duration, and then rapidly quenching it to create a martensitic structure. This process results in parts that are characterized by high strength and toughness, which greatly enhances their anti-collision performance. Hot-formed steel is typically utilized in the manufacture of body structural parts, particularly those intended for intrusion-proof security purposes.

B-Pillar Inner Panel is a structural component of a vehicle’s body that is located inside the B-pillar. The B-pillar is the vertical support located between the front and rear doors of a vehicle, and it plays a critical role in maintaining the structural integrity and safety of the vehicle.

The B-Pillar Inner Panel is typically made of high-strength steel and is designed to fit snugly against the inner surface of the B-pillar. It provides additional support and strength to the B-pillar, which helps to distribute the forces of a collision more effectively and reduce the risk of deformation or collapse.

Dual-phase steel has a microstructure primarily composed of ferrite and martensite, with the martensite structure dispersed in the ferrite matrix in the form of islands. Its low yield ratio, high work hardening index, and bake hardening value make it a preferred material for automotive structural parts. These exceptional properties allow for increased strength and durability in structural components, which in turn enhances the safety and reliability of vehicles.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC340/590DP | 340-440 | ≥590 | ≥22% | – | ≥0.14 | – |

Grade: HC340/590DP

C(max): 0.15

Mn(max): 2.5

Si(max): 0.6

Lower A-pillar Inner Panel is a structural component of a vehicle’s body that is located inside the lower section of the A-pillar. The A-pillar is the vertical support located at the front of the vehicle, between the windshield and the front door, and it plays a critical role in maintaining the structural integrity and safety of the vehicle.

The Lower A-pillar Inner Panel is typically made of high-strength steel and is designed to fit snugly against the inner surface of the lower section of the A-pillar. It provides additional support and strength to the A-pillar, which helps to distribute the forces of a collision more effectively and reduce the risk of deformation or collapse.

Dual-phase steel has a microstructure consisting mainly of ferrite and martensite, with the martensite structure distributed in the form of islands within the ferrite matrix. This unique microstructure, along with its low yield ratio, high work hardening index, and bake hardening value, make dual-phase steel an ideal material for automotive structural parts. Its exceptional properties result in increased strength, durability, and safety in vehicles, making it a preferred choice for the automotive industry.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC420/780DPD+Z | 420-550 | ≥780 | ≥17% | – | – | – |

Grade: HC420/780DPD+Z

C(max): 0.18

Mn(max): 2.5

Si(max): 0.8

Upper A-pillar Inner Panel is a structural component of a vehicle’s body that is located inside the upper section of the A-pillar. The A-pillar is the vertical support located at the front of the vehicle, between the windshield and the front door, and it plays a critical role in maintaining the structural integrity and safety of the vehicle.

The Upper A-pillar Inner Panel is typically made of high-strength steel and is designed to fit snugly against the inner surface of the upper section of the A-pillar. It provides additional support and strength to the A-pillar, which helps to distribute the forces of a collision more effectively and reduce the risk of deformation or collapse.

Dual-phase steel is characterized by a microstructure consisting primarily of ferrite and martensite, with the martensite structure dispersed in the ferrite matrix in the form of islands. Due to its low yield ratio, high work hardening index, and bake hardening value, dual-phase steel is one of the preferred materials for automotive structural parts. This steel provides exceptional strength and durability to structural components, enhancing the safety and reliability of vehicles. Its outstanding properties make it an ideal choice for the automotive industry.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC340/590DP | 340-440 | ≥590 | ≥22% | – | ≥0.14 | – |

Grade: HC340/590DP

C(max): 0.15

Mn(max): 2.5

Si(max): 0.6

C-pillar reinforcement panel is a component of a vehicle’s body structure that is designed to provide additional strength and rigidity to the C-pillar area. The C-pillar is the vertical structure located between the rear door and the rear window on a vehicle’s body.

C-pillar reinforcement panels are typically made from high-strength steel and are strategically located and shaped to absorb and distribute impact forces during a collision. They help to protect the occupants of the vehicle by maintaining the structural integrity of the passenger compartment, reducing the risk of injury from collapsing body structures. In addition to improving safety, C-pillar reinforcement panels also help to reduce noise, vibration, and harshness (NVH) levels by adding stiffness to the body structure. They can also improve vehicle handling and stability by increasing torsional rigidity.

C-pillar inner panel is a component of a vehicle’s body structure that is located on the inside of the C-pillar, which is the vertical structure located between the rear door and the rear window on a vehicle’s body.The C-pillar inner panel is designed to provide additional structural support to the C-pillar area and to protect the occupants of the vehicle in the event of a collision. It is typically made from high-strength steel and is shaped to fit the contours of the C-pillar.

The C-pillar inner panel works in conjunction with the C-pillar reinforcement panel and other components of the vehicle’s body structure to absorb and distribute impact forces during a collision. This helps to maintain the structural integrity of the passenger compartment and reduce the risk of injury to the occupants.

In addition to improving safety, the C-pillar inner panel also helps to reduce noise, vibration, and harshness levels by adding stiffness to the body structure. It can also improve vehicle handling and stability by increasing torsional rigidity.

By precisely controlling the chemical composition of the steel, the plastic strain ratio (r value) and strain hardening exponent (n value) can be improved. This results in a steel with both high strength and excellent cold forming properties, which is ideal for creating complex parts requiring deep drawing. The steel achieves these properties through solid solution strengthening of its elements and a microstructure that lacks interstitial atoms. The steel’s microstructure consists primarily of ferrite, allowing it to achieve a remarkable balance between strength and formability.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC180YD+Z | 180-240 | 340-400 | ≥34% | ≥1.7 | ≥0.18 | – |

Grade: HC180YD+Z

C(max): 0.01

Mn(max): 0.7

Si(max): 0.1

In car design, the C-pillar refers to the third column on the side of the vehicle from the roof to the bottom of the car, which plays an important role in connecting the roof, body and rear of the car. The C-pillar inner panel extension panel is located inside the C-pillar and extends along the extending direction of the C-pillar. Its function is to connect the C-pillar inner panel with other parts in the car body structure to improve the overall strength and rigidity of the car body, and it can also prevent the C-pillar inner panel from breaking and deforming when the body deforms and rolls over.

In low carbon steel, microalloying elements such as niobium, titanium and vanadium are added singly or in combination to form carbonitride particles to precipitate and strengthen. At the same time, through the refinement of grains of microalloying elements, higher strength can be obtained. This steel grade has good weldability. The structure is ferrite + a small amount of carbide.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC340LAD+Z | 340-420 | 410-510 | ≥21% | – | – | – |

Grade: HC340LAD+Z

C(max): 0.11

Mn(max): 1

Si(max): 0.5

Our company: Hengqiao(Shanghai) International Trading Limited

The company’s main business is general GMW standard, Fiat EFE standard, Volvo VDA standard, Nissan NEN standard, Volkswagen VW50065, Ford WSS-M and other standard series of automotive steel.

Looking forward to your inquiry!

We are looking forward to your message:

Send RequestFind your contact person directly here:

To our locations