Metallic material

Innovation | Professionalism

Integrity | Efficiency

Metallic material

Innovation | Professionalism

Integrity | Efficiency

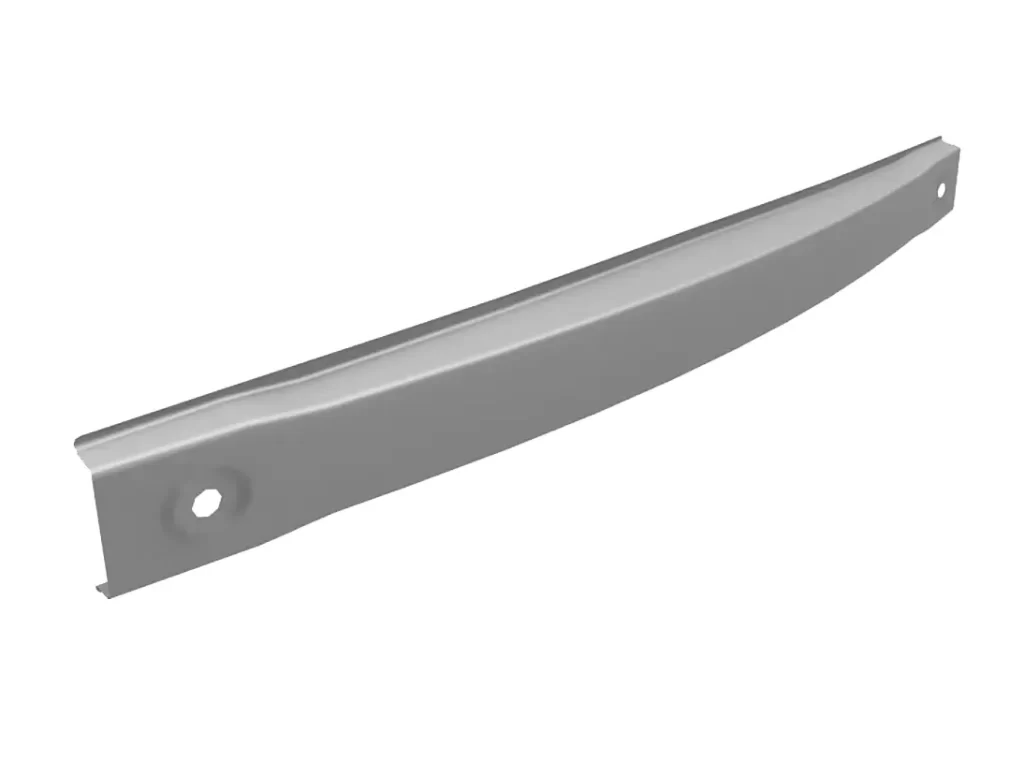

A front anti-collision beam, also known as a front bumper beam or front impact bar, is an important component of a vehicle’s safety system. It is a horizontal metal bar that is installed inside the front bumper of a car or truck, and it is designed to absorb and distribute the energy from a collision, helping to protect the occupants of the vehicle.

The front anti-collision beam is typically made of high-strength steel and is bolted securely to the vehicle’s frame. In a collision, the beam is designed to absorb the impact and prevent the energy from being transferred directly to the passenger compartment of the vehicle. Instead, the energy is dispersed throughout the entire structure of the vehicle, reducing the risk of injury to the occupants.

Steels for hot forming, also known as hot stamping steels, are a type of steel that is processed using a specific heat treatment method to achieve high strength and high toughness. The process involves heating the steel billet above the austenitization temperature, which is the temperature at which the steel transforms into a face-centered cubic crystal structure. The billet is then held at that temperature for a certain period of time to fully transform the microstructure.

After the holding time, the billet is rapidly cooled or quenched to room temperature to form a martensitic structure. This process of quenching and forming a martensitic structure results in a high-strength steel with excellent ductility and toughness. The high-strength and high- Toughness properties of the steel make it ideal for use in body structural parts, especially in intrusion-proof safety structural parts, where it is important to have materials that can withstand high impact loads.

The use of steels for hot forming in body structural parts has been widely adopted in the automotive industry due to its effectiveness in improving anti-collision performance.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC950/1300HS | 950-1250 | 1300-1700 | ≥5% | – | – | – |

Grade: HC950/1300HS

C(max): 0.20-0.25

Mn(max): 1.0-1.4

Si(max): 0.4

The front anti-collision beam energy-absorbing box is an important safety feature in modern automobiles. It is a part of the car’s body structure that is designed to absorb the impact energy of a collision to protect the passengers inside the vehicle.

The front anti-collision beam is typically made of high-strength steel and is located at the front of the car, behind the bumper. The energy-absorbing box is an integral part of the anti-collision beam and is designed to crumple and deform upon impact, absorbing the energy of the collision and reducing the force of the impact on the passengers.

The energy-absorbing box works by compressing and deforming upon impact, which dissipates the energy of the collision and reduces the force of the impact on the passengers. This helps to reduce the risk of injury in the event of a collision, as well as to minimize the damage to the car itself.

Low-alloy high-strength steel is a variety of steel that includes small quantities of alloying components, such as vanadium, titanium, and niobium. These elements are added individually or in combination to low-carbon steel to create carbon and nitrogen compound particles for precipitation. These particles aid in strengthening the steel, increasing its durability, and resistance to deformation.

Besides boosting the steel’s strength, microalloying components also refine the steel’s grain structure. This refinement enhances the uniform distribution of the alloying components and helps avoid the creation of large, brittle grains. As a result, the steel is both strong and ductile, meaning it can endure high levels of stress without breaking or deforming.

Low-alloy high-strength steel is sought-after because of its excellent weldability, which means it can be welded without compromising its strength or durability. This makes it a popular choice for applications requiring welding, such as in the construction of bridges, buildings, and pipelines.

Typically, the microstructure of low-alloy high-strength steel consists of ferrite and a small amount of carbide. Ferrite is a type of iron that is relatively soft and ductile, whereas carbide is a hard, brittle compound that includes carbon and other elements.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC340LAD+Z | 340-420 | 410-510 | ≥21% | – | – | – |

Grade: HC340LAD+Z

C(max): 0.11

Mn(max): 1

Si(max): 0.5

Our company: Hengqiao(Shanghai) International Trading Limited

The company’s main business is general GMW standard, Fiat EFE standard, Volvo VDA standard, Nissan NEN standard, Volkswagen VW50065, Ford WSS-M and other standard series of automotive steel.

Looking forward to your inquiry!

We are looking forward to your message:

Send RequestFind your contact person directly here:

To our locations