Metallic material

Innovation | Professionalism

Integrity | Efficiency

Metallic material

Innovation | Professionalism

Integrity | Efficiency

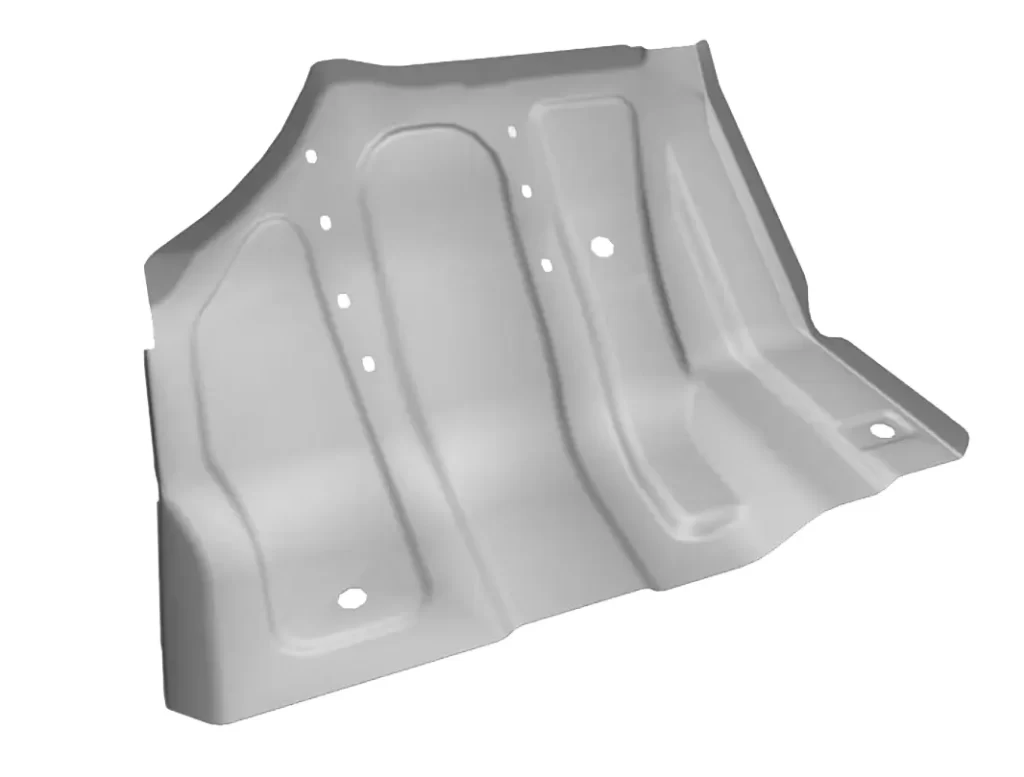

Front floor pan is an automotive part that is a metal plate on the underside of the vehicle, usually under the front seats. It is part of the vehicle’s chassis that supports and protects the underbody and underbody components of the vehicle, such as the engine, transmission and suspension. It is usually made of steel or aluminum for strength and corrosion resistance. If the front floor panel is damaged or corroded, it may affect the structural integrity and stability of the vehicle, resulting in driving safety concerns.

The steel contains a specific quantity of solid solution carbon and nitrogen atoms, and its strength can be improved by introducing strengthening elements like manganese and phosphorus. It is commonly used for the outer body of automobiles, as it undergoes age hardening, after and baking at a particular temperature, leading to an increase in its yield strength. The structure of the steel is ferrite.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC180BD+Z | 180-240 | 300-360 | ≥34% | ≥1.5 | ≥0.16 | ≥30 |

Grade: HC180BD+Z

C(max): 0.04

Mn(max): 1

Si(max): 0.5

Dual phase steel is a preferred material for automotive structural parts because of its microstructure, which consists primarily of ferrite and martensite. The martensite structure is dispersed in the ferrite matrix in the form of islands. This steel has a low yield work ratio, a high hardening index, and a bake hardening value.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC550/980DPD+Z | 550-730 | ≥980 | ≥10% | – | – | – |

Grade: HC550/980DPD+Z

C(max): 0.23

Mn(max): 3

Si(max): 1

The microstructure of dual phase steel, which is mainly composed of ferrite and martensite, makes it a desirable material for automotive structural parts. The martensite structure is dispersed in the form of islands within the ferrite matrix. Dual phase steel has a low yield ratio, high work hardening index, and bake hardening value, all of which contribute to its preferred usage in automotive structural applications.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC420/780DPD+Z | 420-550 | ≥780 | ≥17% | – | – | – |

Grade: HC420/780DPD+Z

C(max): 0.18

Mn(max): 2.5

Si(max): 0.8

High-strength carbon structural steel is a variety of steel that achieves increased strength by incorporating small amounts of alloy elements like Si and Mn, primarily through the process of solid solution strengthening. The primary microstructure of this type of steel is composed of ferrite and pearlite.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| B280VK | 280-400 | ≥440 | ≥29% | – | – | – |

Grade: B280VK

C(max): 0.15

Mn(max): 2

Si(max): 0.5

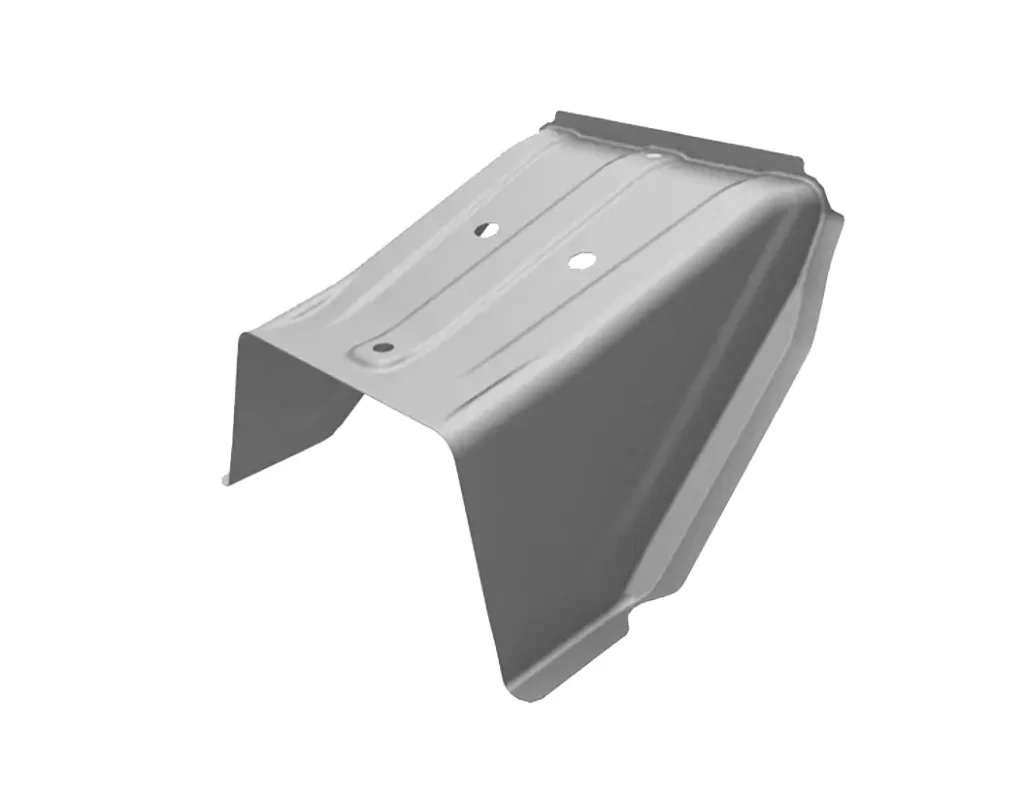

In the front floor assembly of a car, “center channel” usually refers to the central tunnel cover, also known as the center console tunnel cover. The cover panel sits on the floor between the front seats and covers the center tunnel, protecting the vehicle’s drivetrain and other parts from external damage.

The process of creating hot-formed steel involves heating a billet above its austenitization temperature, holding it for a specific period, and then pressing and quenching it to form a martensitic structure. This process results in high strength and toughness of the part, effectively enhancing the part’s anti-collision performance. Hot-formed steels are primarily used for body structural parts, particularly for intrusion-proof security structural parts.

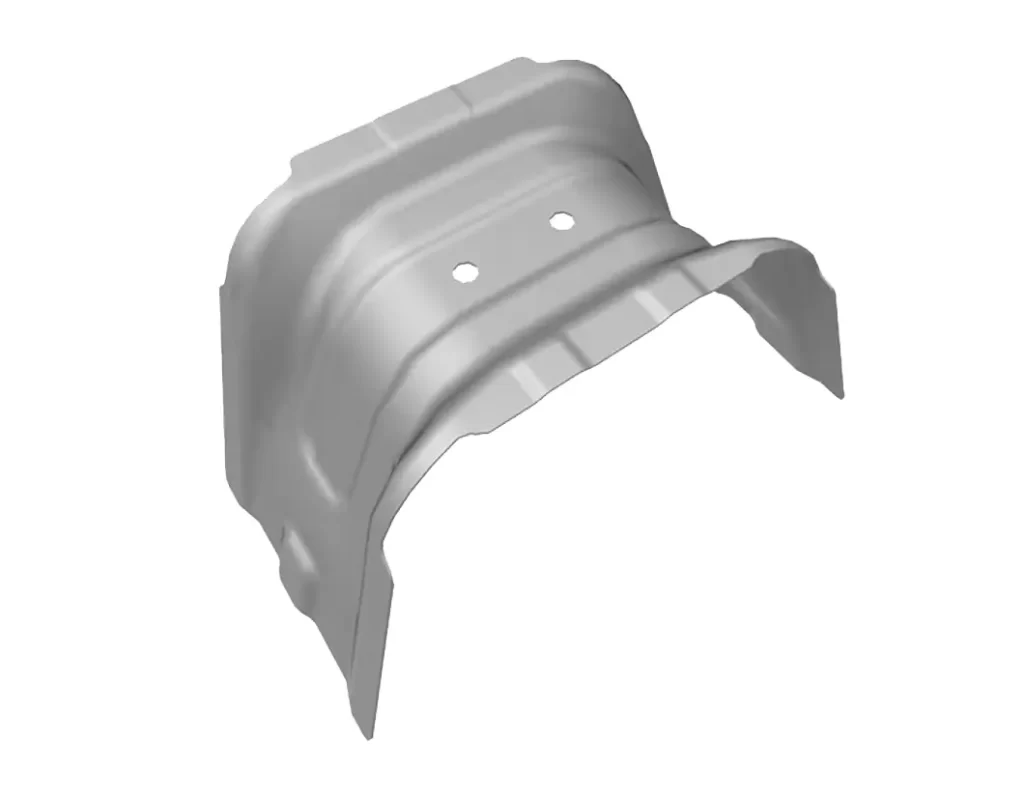

“Second crossmember” refers to a structural component in the front floor assembly of a vehicle. It is typically a horizontal beam that runs across the vehicle’s underbody and provides support for the vehicle’s suspension system. The second crossmember is positioned behind the first crossmember, which is located closer to the front of the vehicle. Together, these crossmembers help to distribute the weight of the vehicle and absorb impact forces during a collision.

Dual phase steel is a favored material for automotive structural parts due to its microstructure, which is primarily composed of ferrite and martensite. Within the ferrite matrix, the martensite structure is dispersed in the form of islands. Dual phase steel boasts a low yield ratio, high work hardening index, and bake hardening value, all of which make it highly suitable for use in automotive structural applications.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC420/780DPD+Z | 420-550 | ≥780 | ≥17% | – | – | – |

Grade: B280VK

C(max): 0.18

Mn(max): 2.5

Si(max): 0.8

Our company: Hengqiao(Shanghai) International Trading Limited

The company’s main business is general GMW standard, Fiat EFE standard, Volvo VDA standard, Nissan NEN standard, Volkswagen VW50065, Ford WSS-M and other standard series of automotive steel.

Looking forward to your inquiry!

We are looking forward to your message:

Send RequestFind your contact person directly here:

To our locations