The Advantages and Sustainability of Galvanized Steel: A Comprehensive Guide

2023-05-15

Introduction to galvanized steel

Galvanized steel is a type of steel that has been coated with a layer of zinc to protect it from corrosion. The process of coating steel with zinc is called galvanization. Galvanized steel is widely used in various industries due to its corrosion resistance, durability, and low cost.

The process of galvanization involves immersing the steel in a bath of molten zinc or by using an electrochemical process to deposit a layer of zinc onto the steel surface. The zinc coating acts as a sacrificial anode, protecting the underlying steel from corrosion.

Galvanized steel is commonly used in construction for things like roofing, siding, and gutters because it is strong, durable, and can withstand harsh weather conditions. It is also used in the automotive industry for parts such as body panels and chassis components. Additionally, it is used in the manufacture of pipes, fencing, and agricultural equipment.

Common Types of Galvanized Steel

There are several types of galvanized steel that are commonly used in different applications. These types include:

Hot-dip galvanized steel: This is the most common type of galvanized steel, where the steel is immersed in a bath of molten zinc to create a thick coating of zinc on the surface.

Electrogalvanized steel: This type of galvanized steel is produced by electroplating the steel with a thin layer of zinc. It is typically used for applications where a thinner coating is needed.

Galvannealed steel: This is a type of galvanized steel that has been annealed to create a zinc-iron alloy coating on the surface. It is commonly used in automotive and construction applications where a high-strength, corrosion-resistant material is needed.

Continuous galvanized steel: This type of galvanized steel is produced by passing the steel through a bath of molten zinc on a continuous basis. It is used for applications where a continuous length of coated steel is needed, such as in the manufacture of tubing or wire.

Zinc-aluminum-magnesium alloy coated steel: This is a relatively new type of galvanized steel that contains a coating of zinc, aluminum, and magnesium. It is highly corrosion-resistant and is commonly used in outdoor and marine applications.

Each type of galvanized steel has its own advantages and disadvantages, and the choice of which type to use depends on the specific application and requirements.

What are the advantages of galvanized steel?

Galvanized steel offers several advantages over other materials, including:

Corrosion resistance: Galvanized steel is highly resistant to corrosion and rust, making it ideal for use in harsh environments. The zinc coating acts as a barrier between the steel and the environment, preventing rust and corrosion from forming.

Durability: Galvanized steel is a very durable material that can withstand extreme temperatures and weather conditions. It is also resistant to damage from impacts and other forms of physical stress.

Low maintenance: Galvanized steel requires very little maintenance and is easy to clean. The zinc coating helps to prevent dirt and debris from sticking to the surface, making it easy to wipe clean.

Cost-effective: Galvanized steel is a relatively inexpensive material, especially when compared to other corrosion-resistant materials like stainless steel. This makes it a popular choice for applications where cost is a primary concern.

Easy to work with: Galvanized steel is easy to cut, shape, and weld, making it a versatile material for a wide range of applications.

Where is galvanized steel commonly used?

Galvanized steel is used in a wide range of applications, including:

Construction: Galvanized steel is commonly used in the construction industry for roofing, siding, gutters, and downspouts. It is also used for structural support, such as in steel framing, beams, and columns.

Automotive: Galvanized steel is used in the automotive industry for body panels, exhaust systems, and chassis components. It is valued for its durability, corrosion resistance, and ability to withstand impact.

Electrical: Galvanized steel is used for electrical conduits, cable trays, and support systems due to its strength and corrosion resistance.

Agriculture: Galvanized steel is used for fencing, gates, and other agricultural equipment because of its strength, durability, and ability to withstand harsh weather conditions.

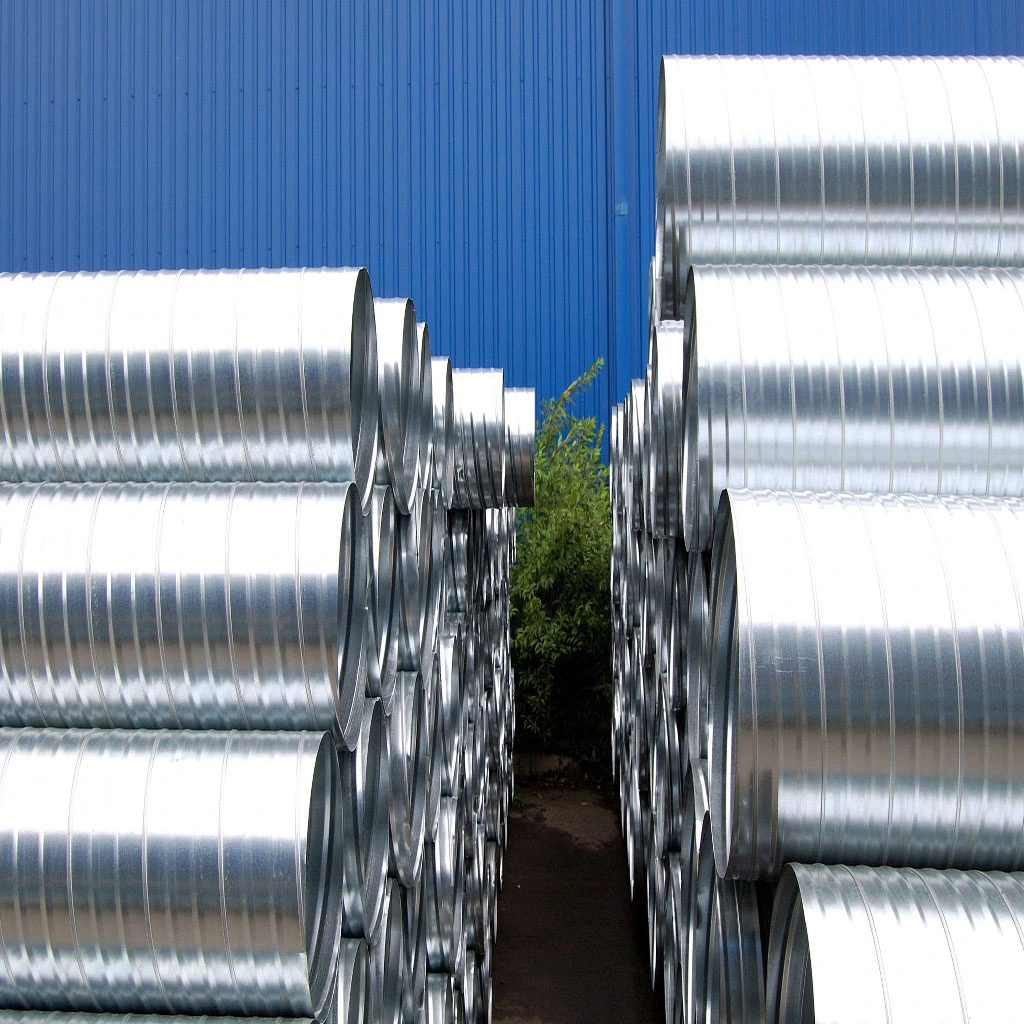

Industrial: Galvanized steel is used in a wide range of industrial applications, including storage tanks, pipes, and scaffolding. It is valued for its corrosion resistance and ability to withstand extreme temperatures.

Household: Galvanized steel is used in many household items, such as garbage cans, mailboxes, and laundry tubs. It is valued for its durability, corrosion resistance, and affordability.

The Sustainability of Galvanized Steel

Galvanized steel is a sustainable material that offers a number of environmental benefits. The zinc coating on galvanized steel provides a long-lasting, protective barrier that helps to extend the life of the steel, reducing the need for frequent replacements. This can help to conserve natural resources and reduce waste. Additionally, galvanized steel is a highly recyclable material, with the ability to be recycled indefinitely without losing its properties or quality. This makes it a preferred choice for manufacturers looking to reduce their environmental impact and meet sustainability goals. Furthermore, galvanizing is a relatively low-energy process, using less energy compared to other methods of corrosion protection. These environmental benefits, combined with the cost-effectiveness and durability of galvanized steel, make it a sustainable choice for a wide range of applications.